PVD quality considerations

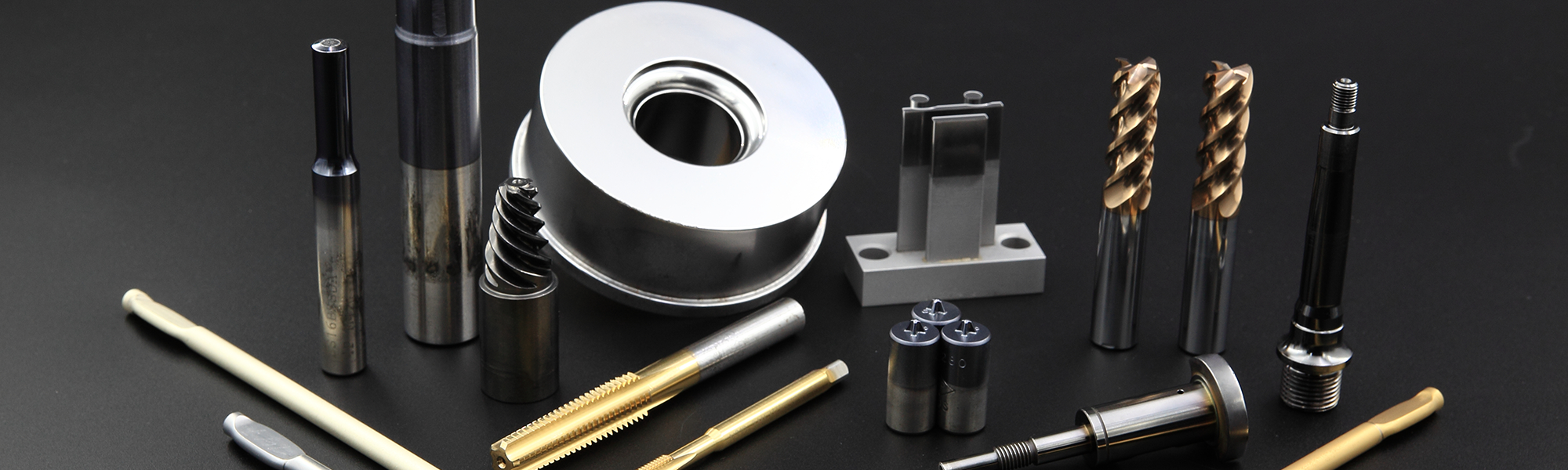

◆ Cutting

tools and molds should avoid burnout and burrs during grinding.

◆ The

key surface of the workpiece cannot be treated with phosphoric acid film and

galvanizing, and the surface should avoid adhesion such as residual glue, wax,

PVC, etc. If the workpiece must be coated with anti-rust oil, non-silicon-based

oil should be selected.

◆ The

temperature of the PVD process, generally about 400 to 500 °C, affects the

adhesion between the coating and the substrate. In order to avoid the decrease

in the hardness of the substrate, dimensional changes or heating deformation

after PVD, materials with heat resistance above 500 °C must be selected, such

as high speed steel, hot-work die steel.

◆ Heat

treatment should avoid the salt bath method as possible, and attention must be

paid to whether there are residues on the surface of the workpiece or in the

gap, which will cause poor adhesion of the coating.

◆ After

electrical discharge machining, a white layer and a heat-affected deterioration

layer are easy to form on the surface. This layer is in a brittle state and has

poor adhesion to the substrate. If PVD sputtering is carried out, cracks are

more likely to occur on the hard coating, which must be treated by grinding and

polishing until the white layer is completely removed.

◆ If there are rust spots and black skin on the surface of the workpiece,

impurities will be precipitated during the coating process and the coating will

be poorly adhered. If the workpiece is welded or repaired, it must not contain

impurities such as flux and must be able to withstand vacuum and high

temperature(600°C).

◆ For

complex-shaped molds such as deep-hole slits, the substance to be deposited is

not easy to enter during PVD processing. The

effective depth of the hole treatment is equivalent to the hole diameter;

beyond this range, the thickness, adhesion, and crystal structure of the

coating will drop sharply and deteriorate.

◆ The

surface roughness of the mold processed by PVD will have a certain degree of

influence. Generally speaking, the smaller the substrate roughness, the lower

the friction coefficient, the better the adhesion of the coating, and the

smaller the pressure on the surface. As the load of working conditions

increases, the roughness requirements become stricter. Therefore, such molds

should be properly polished.